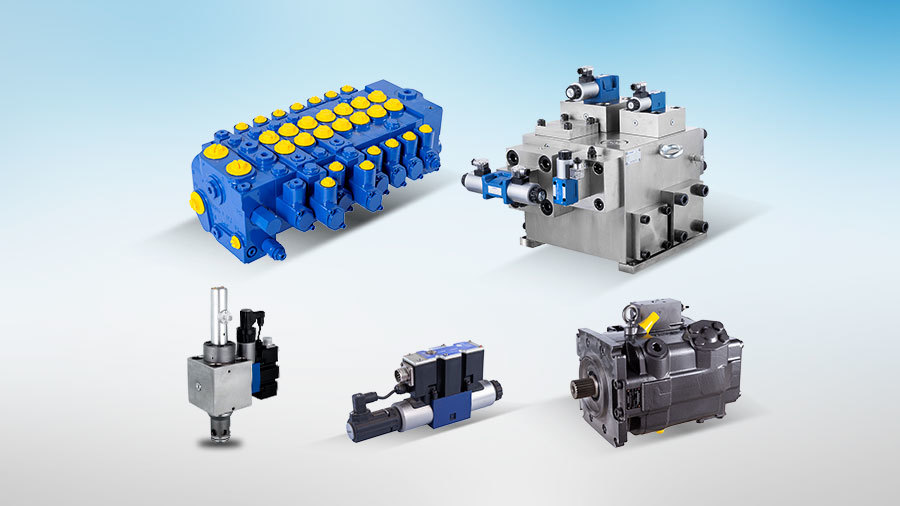

The company's products are widely used in different host products and technical equipment in various fields of the national economy, supporting industries such as industrial equipment and walking machinery. The products are mainly used in hydraulic transmission systems on host machines such as machine tools, metallurgical machinery, renewable resources, and engineering machinery.

|

Two-way Cartridge Valve |

|

Two-way cartridge valve is applied to the 2500 ton metal gantry shear hydraulic packaging machine and gantry shear hydraulic machine in the recycling industry of circular economy, energy conservation and environmental protection. |

Two-way cartridge valve is applied to the 3500/580 ton heavy-duty dual station forging hydraulic press, specializing in the production of key core components such as bearings for ultra large power generators, nuclear power plants, and valves for ships. |

Two-way cartridge valve is applied to the plate rolling machine, which can achieve sheet metal forming, cold and hot processing, and has high precision through proportional speed control and synchronous control, with precise forming dimensions. |

|

Two-way cartridge valve is applied to woodworking machinery, which can achieve high-pressure pressing of multi-layer wood boards to achieve high-density pressing and forming of wooden boards. It has the characteristics of high work efficiency, reliable work, strong stability, and easy maintenance. |

Two-way cartridge valve is used in shield tunneling machines to achieve functions such as propulsion, spiral conveying, pipe segment assembly, and grouting. It has the characteristics of precise work, high efficiency, low noise, and on-demand control mode selection. |

Two-way cartridge valve is applied to the slide valve combination of cotton picking machines, which can achieve functions such as static hydraulic walking, cotton picking head following lifting, cotton box flipping, and cotton conveying and compaction. It has the characteristics of high integration, load sensitivity, and proportional speed regulation. |

|

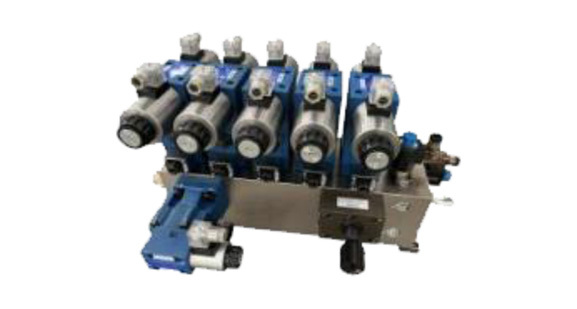

Sectional Hydraulic Control Valve |

|

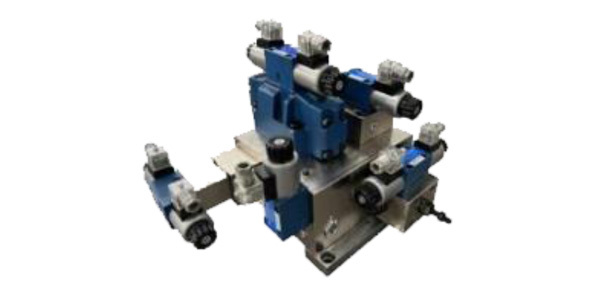

TET series Sectional hydraulic control valve is applied to wheeled excavators, which has the characteristics of load sensitivity, proportional flow distribution, anti flow saturation, small pressure loss, and energy conservation. |

THD series sectional hydraulic control valve is applied to medium and micro pile drivers, which can achieve dual pump oil supply and soft composite action. |

TRM series sectional hydraulic control valves are applied to medium and large tonnage cranes, and can be combined into corresponding reversing routes according to needs. They have characteristics such as load sensitivity, proportional flow distribution, anti flow saturation, energy saving, orderly operation, and comfortable operation. |

|

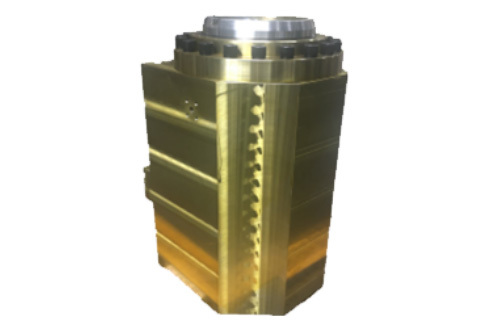

Piston Pump |

|

TFA4V series piston pump is used in marine equipment, with a rated pressure of 31.5 megapascals and a maximum pressure of 35 megapascals. It is modular in design and can adjust the output flow rate steplessly by adjusting the swash plate angle. It has various variable control methods, excellent oil suction characteristics, low noise level, short response time, and can add visual swing angle indicators as needed to achieve axial drive of multi pump systems. |

TFA7V series piston pump is applied to bending machinery, suitable for open systems, with a rated pressure of 35 megapascals and a maximum pressure of 40 megapascals. It has a compact structure, high power density, and multiple variable control methods such as constant power, constant pressure, and electric proportion, which can achieve axial drive of multi pump systems. |

|

TFA10V series piston pump is applied to agricultural machinery, suitable for open systems, with a rated pressure of 28 megapascals and a maximum pressure of 35 megapascals. It has multiple variable control methods such as constant pressure, load sensitivity, and constant power. It has excellent oil absorption characteristics, high power density, low noise, and can achieve axial drive of multi pump systems. |

TET series multi way valve is applied to wheeled excavators, which has the characteristics of load sensitivity, proportional flow distribution, anti flow saturation, small pressure loss, and energy conservation. |

|

Hydraulic Cylinder |

|

MB series CNC hydraulic cylinder is applied to large and medium-sized CNC bending machines. The working pressure, stroke, and speed of the hydraulic cylinder are adjusted through the integrated electro-hydraulic servo valve on the cylinder, thereby changing the closing speed, height, and force of the upper and lower mold openings of the bending machine. It has the characteristics of compact structure, high integration, convenient installation, high precision of repeated adjustment, and reliable operation. |

WST series CNC hydraulic cylinder is applied to CNC sheet metal bending machines. The oil entering the hydraulic cylinder is controlled by an electro-hydraulic servo valve installed at the end of the cylinder barrel to adjust the working stroke of the hydraulic cylinder, thereby changing the closing height of the upper and lower die openings of the bending machine and achieving the bending requirements for different sheet materials. It has the characteristics of easy installation, high precision of repeated adjustment, reliable operation, and good sealing performance. |

|

WC67Y series hydraulic cylinder is used in mechanical sheet metal bending machines and is a type of worm gear transmission structure oil cylinder. The closing height of the upper and lower molds of the mechanical sheet metal bending machine, which is the working stroke of the hydraulic cylinder, is driven by the worm gear to rotate the screw shaft, thereby promoting the movement of the adjusting nut and meeting the working requirements of different bending angles of the sheet metal. It has the characteristics of fast return speed and reliable sealing. |

WBT series compensation hydraulic cylinder is applied to roll bending machines. It is a hydraulic cylinder that compensates for the deflection of the workbench. The bending machine produced using this technology can achieve high dimensional accuracy and consistency in bending the produced workpiece. It has the characteristics of easy installation, reliable operation, and good sealing performance. |

|

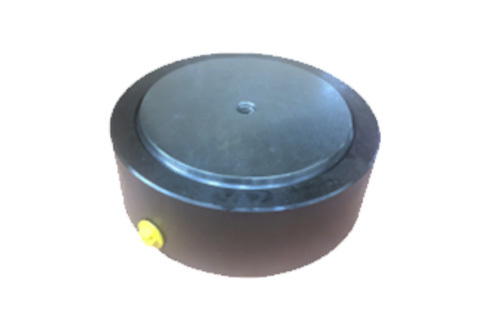

Prefill Valve |

|

TCF type prefill valve is mainly used in forging machines, with a diameter of 40mm-100mm. It has the characteristics of low opening pressure, good self suction performance, smooth flow channel, small flow resistance, low control pressure, and reliable reset. |

SCF type prefill valve is applied to fast forging machines. This product is a dual control prefill valve with a diameter of 150mm-400mm. Relying on spring reset, the opening speed is controlled by the size of the pilot flow, and has the characteristics of smooth flow channels, low flow resistance, and reliable reset. |

|

CF type prefill valve is used in high-speed punching machines, with a diameter of 100mm to 400mm. It has the characteristics of low opening and control pressure, good self suction performance, small flow resistance, reliable reset, and stable performance. |

TRCF type prefill valve is used in bending machines, with a diameter of 100mm-550mm. It has the characteristics of low opening and control pressure, good self suction performance, small flow resistance, reliable reset, and stable performance. |

|

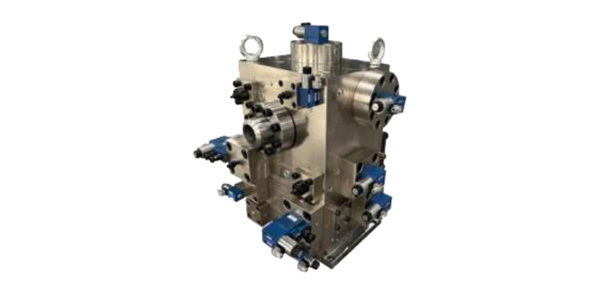

Hydraulic System |

|

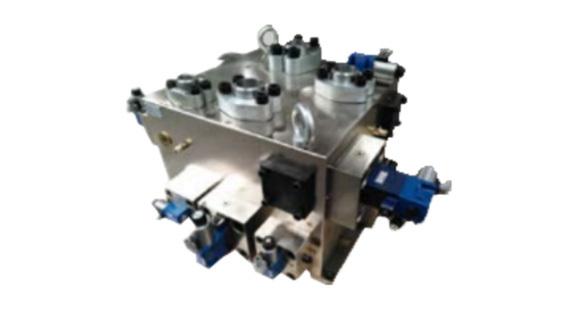

The electro-hydraulic integrated control system is applied to metal packaging machines. This product drives a high-pressure high-speed piston pump through a servo motor, achieving high flow output, high power efficiency, and a 20% increase in main engine speed compared to ordinary systems. The standby energy consumption fully meets the requirements of energy conservation and environmental protection. |

The electro-hydraulic integrated control system is applied to metal gantry shears. This product drives a high-pressure high-speed piston pump through a servo motor, achieving high flow output and repeated power efficiency. The number of shears increases by 25% compared to ordinary systems, and the standby energy consumption is zero, fully meeting the requirements of energy conservation and environmental protection. |

|

The electro-hydraulic integrated control system is used for the processing and forging of aerospace bars and cylindrical materials. By increasing the forging frequency, it solves the problems of small forging temperature range and high tempering cost of titanium alloys, greatly improving traditional forging processes. |

The electro-hydraulic integrated control system is used for the pressing and forming production of high-speed rail wheels and rings. It can achieve one-time pressure forming of forged wheels, breaking the traditional casting process of wheels, reducing the weight of wheels, and improving the bearing strength. |

Focus on Taifeng

66 Haichuan Road, High-tech Zone, Jining City, Shandong Province